High Accurate Resistance Measurements

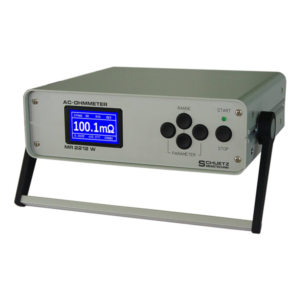

MR 1012 S

For manufacturing control systems, 5 / 10 / 20 measurements per s.

Owing to its high measuring rate, its compact and robust design, ist accuracy and long-term stability, the digital ohmmeter MR1012S can be used in applications with high requirements concerning the measuring stability and reliability. This is guaranteed by the integrating measuring method according to the quotient principle, the compensation of all thermoelectric forces and other offset voltages, as well as the suppression of interference voltages in the measuring and data lines induced e.g. by HF.

The sophisticated recognition of contact errors at the holding device itself is one of the most important features, as it enables you to distinguish between such errors and actual defects of the test object. The corresponding error messages, as well as the actual defects of the test object are not only transferred to the control system, but also displayed clearly on the MR 1012S front panel.

The MR1012S features a 20mV limitation which can be connected / disconnected, in order to carry out dry measurements at contacts. Further an automatic measuring system is provided which is activated in case the value measured is below / above the measuring range. The instrument is also provided with an input protection against surges, which can occur during the measurement of inductive components, for example.

In this case the user can activate a measurement delay in order to give the measuring current which builds up slowly with an inductance the time required to become stable. All measuring conditions set are stored internally, and are preserved even when the MR1012S is switched off.

For this reason it is only necessary to program the instrument once via the RS232C interface, in order to operate the instrument with these parameters at manual measuring setups, with an industrial PLC system or via RS232C. The MR1012S has a resolution of 18000 steps, so that even in the worst case (i.e. the measured value requires step 18001 and the next higher range must be used) the measuring error is not affected noticeably.

The MR1012S is designed to be used within industrial and manufacturing control systems where high accuracy and remote controlled operation is strongly recommended. Furthermore, the easy to read front panel supports complete manual control making the MR1012S an ideal choice for laboratory use. The device can fully be remote controlled via a V24 RS232C or an IEEE-488 complianced interface. For manual control a footswitch can be connected (optional). A lot of ‘add-ons’ are available, e.g. special software for surface measurements, LCD-Display, AC-measurements.

| Resistance measurement | |

| Range | 10 mΩ – 100.00 kΩ, decadic |

| Overrange | +80 %, to 18000 |

| Resolution | 1 ;@Range 1 mΩ |

| Condition for Error Specs | @ 10 Measurements / s ; 20/23°C |

| Max. Measurement Error | ± 0.03 % RDG ± 0.02 % RNG |

| Additonal Temperature Error | ± 0.0002 % x (|t| – 20/23°C) RDG |

| Long term Stability | ± 0.002 % / Year RDG |

| Measuring Method | integrating dual slope quotient |

| Object Connection | 4-Pole due to Kelvin |

| Current | 100 ;A (10 kΩ) to 1 A (1, 10 mΩ) |

| Max. Lead Resistance | 2Ω (tested), 3Ω max. @ 1A |

| Range selection | automatically, using keypad, via RS232 |

| Display | LED, 3 ½ or 4 ½ digits, selectable |

| Speed | 5, 10, 20 Measurements per second available |

| Temperature measurement | |

| Programmable Cycles | every 1st to 1000thmeasurement |

| Reference | conversion to 20 °C or 23 °C |

| Temeprature Coefficient | - 9.99 to + 9.99 ‰/K via RS232 or Keypad |

| Inputs | PT 100 probe, or via keypad or RS232 |

| Error detection | prior to EVERY single measurement |

| Current Connection Errors | display: ‚CUR‘, RS232: ‚ECUR‘ |

| Sense Connection Errors | display: ‚SEN‘, RS232: ‚ESEN‘ |

| Overrange > 80% | display: ‚OVL‘, RS232: ‚EOVL‘ |

| Thermoelectric Force Compes. | prior to every single cycle, automatically |

| Limit Values | |

| Input | using Keypad, via RS232 |

| Off-Limit Condition | visible by LEDs, via RS232, via PLC |

| Start of Measurment | using Keypad, via RS232 (pot.free) and IEEE – 488, via PLC (potential free contact), via Foot Switch (optional) |

| Interfaces | RS232C (full device control) PLC (<,=,>,EOC,GO,REM) Printer (parallel, ANSI standard) IEEE – 488 (optional) |

| Environment | Operating: 0° - +50°C, RHD 80% max. Storage: -20°C … +70°C, both not condensing |

| EMC | IEC801-2/-3 , EN55011 |

| Dimensions | 260 x 80 x 240 mm (WxHxD) |

| Weight | approx. 3 kg |

| Multiplexer | within the normal dimensions: This instrument can be expanded to 6/10 measuring channels, 10 with common ground (electronic switches), 6 all separate with six 4- pole relais (Options). For more channels (up to 50) see our MR1012MP. |

- Measuring range from 10 mΩ – 100 kΩ, decadic

- Overrange up to 80 %

- max. resolution of 1 µΩ

- Selectable display, 3 ½ or 4 ½ digits

- Models available with 5, 10 or 20 measurements per second

- Measuring error ± 0,03% of MV ± 0,02 % of EV

- Temperature measurements and conversion to 20 °C or 23 °C

- Limit parameters as well as visual enhancements (ok, too low, too high), including switchable acoustic signal

- RS232C port to get full external control over the instrument

- Centronics printer port

- PT 100 1/10 DIN – temperature probe:

4-pol. MiniDIN connector

cable length 1,5 m

F = ±(0,03°C+0,0005•|t|) - Other Temperature Probes:

Infrared and Thermoelectric device - Analog Output:

for xt-paper recorder; full range = 10 V - IEEE-488 / IEC-625 interface:

control the instrument via GPIB - Multiplexer:

internal multiplexer up to 10 channels

(higher channel count by request) - Foot switch:

to start measurement externally

cable length 3 m - Software MR1012 XFER

sends measurement values to any

Windows© application (e.g.Excel©)

For Windows© 98 / NT / ME / 2000 / XP.

Features

-

- Cable 4pin, 2 m long, Amphenol &

banana plugs (4x, red, yellow, green, blue) - Cable 4pin, 2 m long, Amphenol &

various Kelvin clamps - DKD – calibration certificate from the

“Deutscher Kalibrierdienst” - PT 100 10/10 DIN – temperature probe:

4-pol. MiniDIN connector

cable length 1,5 m

F = ± (0,03°C+0,0005•|t|)

- Cable 4pin, 2 m long, Amphenol &

DIN EN ISO 9001:2008